The selection of ion exchange resins involves many aspects. The following are some of the main selection principles.

I. Selection based on the purpose of ion exchange

1. Removal of cations: If you need to remove cationic impurities in water to soften water or remove metal ions, you can choose a sulfonic acid type strong acid cation exchange resin. It can effectively exchange cations in water with hydrogen ions on the resin. It is often used in the pretreatment of industrial boiler water to prevent scale formation and extend the life of equipment. If you only need to remove ions with strong adsorption in water (such as Ca²⁺, Mg²⁺, etc.), you can choose a weak acid resin. If you need to remove cations with weak adsorption in raw water (such as K⁺, Na⁺), you must use a strong acid resin.

2. Removal of anions: If you need to remove anions in water, you can choose a strong alkaline anion exchange resin containing a quaternary ammonium functional group. This type of resin is often used in the preparation of ultrapure water in the electronics industry to remove trace anionic impurities. If you need to remove anions (such as HCO₃⁻, HSiO₃⁻) in the raw water, you must use a strong alkaline resin. If there are more organics in the raw water or the radius of the ions to be removed is larger, a macroporous resin with a larger cross-linked mesh should be used.

3. Simultaneous removal of anions and cations: If you need to prepare high-purity deionized water or perform deep desalination, mixed bed ion exchange resins are often used. That is, strong acid cation exchange resins and strong alkaline anion exchange resins are mixed and loaded into columns in proportion, which can efficiently remove anions and cations at one time to obtain high-purity water. The advantages of this resin are strong ion exchange capacity, wide pH range, and fast exchange speed. It is often used in industrial wastewater treatment and chemical raw material refining.

II. Selection based on the characteristics of the resin

1. Exchange capacity: It is one of the core indicators of ion exchange resins, which determines the adsorption capacity and treatment effect of the resin. When selecting, the required exchange capacity should be determined based on the type and concentration of ions in the treated water and the treatment effect to be achieved. Generally speaking, for the treatment of high-concentration ion water, a resin with a larger exchange capacity should be selected. At the same time, weak resins generally have larger exchange capacity than strong resins, but their mechanical strength may be poorer; the same type of resins have different exchange capacities due to different crosslinking degrees. Resins with low crosslinking degrees have large exchange capacities, while resins with high crosslinking degrees have small exchange capacities.

2. Resin structure: Gel-type resins have a relatively compact structure and are suitable for general water treatment; macroporous and ultra-macroporous resins have more open internal structures, have better permeability and exchange capacity for macromolecular substances, and are suitable for treating water containing more organic matter.

3. Stability: refers to the ability of ion exchange resins to maintain their stable performance during use. When selecting, attention should be paid to aspects such as chemical stability, thermal stability, and mechanical stability to ensure that the selected resin can maintain good performance during the treatment process and avoid performance degradation or failure. For example, some resins may degrade in acidic or alkaline conditions, or disintegrate at high temperatures, so it is necessary to select suitable resins according to the water quality conditions and temperature requirements of the specific application scenario.

4. Selectivity: refers to the adsorption capacity of ion exchange resins for specific ions. Different ion exchange resins have different selectivities for different ions. Therefore, in practical applications, it is necessary to select resins with appropriate selectivity according to the types and concentrations of ions in the water. For example, for water containing multiple ions, resins with better selectivity can be selected to improve the treatment effect and reduce the resin consumption.

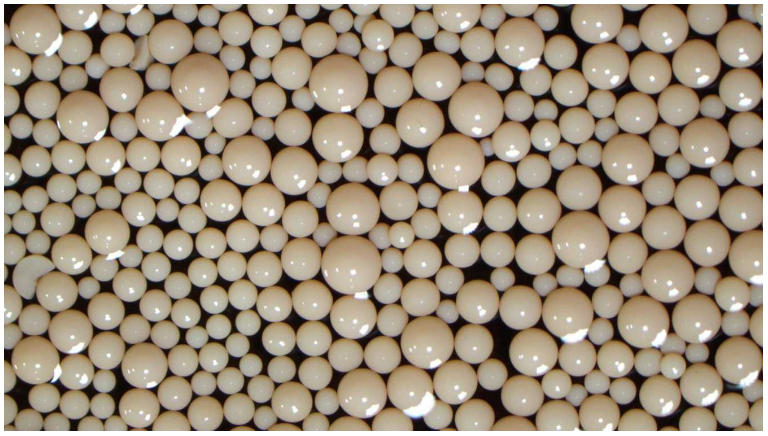

5. Particle size and uniformity: The size of resin particles affects the exchange rate and water flow resistance. Small particles have a fast exchange rate but are easy to clog, and large particles have low resistance but slow exchange rate. Particle uniformity affects bed uniformity and exchange efficiency, and particle size can be selected as required.

6. Density: It includes wet true density and wet apparent density. Wet true density affects the sedimentation and backwashing stratification of resin in water, and wet apparent density is used to calculate the resin loading. Both are critical to the design and operation of ion exchange columns.

7. Swelling degree: Ion exchange resins contain a large number of hydrophilic groups, and they absorb water and swell when in contact with water. When the ions in the resin change, expansion will occur, increasing the volume of the resin. When designing an ion exchange device, the swelling degree of the resin must be considered to adapt to the changes in resin volume caused by ion conversion in the resin during production operation.

III. Choose according to the application scenario

1. Drinking water treatment: resins that are harmless and pollution-free to the human body should be selected, and must meet strict standards.

2. Chemical production: resins that can withstand harsh environments such as high concentration, high temperature, strong acid and alkali should be selected.

3. Food industry: used for decolorization and desalination of sugar solution and purification of condiments such as monosodium glutamate, it is necessary to select food-grade safe resins.

4. Hydrometallurgy: used to extract and concentrate valuable metals such as rare earth elements and precious metals from ore leachate, it is necessary to select resins with high selectivity and good recovery performance.

5. Other industries: such as electronics industry, nuclear technology, bioengineering, etc., need to select suitable resins according to specific needs.

IV. Choose according to economy and environmental protection

1. Regeneration efficiency and difficulty: Resins that are easy to regenerate and have good performance recovery after regeneration can reduce operating costs. When selecting, it is necessary to examine the regeneration efficiency and difficulty of the resin.

2. Price and service life: The price and service life of ion exchange resins of different brands and models are different. When choosing, you need to comprehensively consider price, service life and operating costs, and choose the resin with the best cost performance.

3. Environmental protection: With the continuous improvement of environmental awareness, environmental friendliness has become an important consideration when choosing ion exchange resins. When choosing, you should pay attention to whether it is an environmentally friendly product, whether it is renewable, and whether harmful waste is generated during the treatment process.

V. Choose according to supplier service and technical support

1. Brand reputation: Choose brand ion exchange resins with good reputation and high credibility, which have more guaranteed quality, stable functions and long service life.

2. Quality certification: Check whether the resin has NSF, ISO and other certifications. Certified resins meet the requirements of the specifications and are suitable for occasions with requirements for water quality.

3. Technical support: Reliable suppliers can not only provide high-quality products, but also provide customized solutions, technical consultation and after-sales support according to the specific needs of users. This is crucial to ensure the efficient and stable operation of the ion exchange system.

The selection criteria of ion exchange resin involve many aspects, including ion type, exchange capacity, stability, application requirements, economy and environmental friendliness. In practical applications, comprehensive consideration and balance are required to select the most suitable ion exchange resin to ensure better treatment efficacy.

Extrepure Resin(Shanghai) CO.,LTD